|

Problem:

A steel

service center operates a mid-1970ís vintage 60" x .028"-.120" x 150 FPM

hump table-positive stop type cut-to-length line that was unable to hold

length and squareness tolerances that its customers were demanding. In

addition, the old sheet stacker was producing sloppy, staggered sheet packs

that were becoming unacceptable to its customers. Something had to be done

in order to maintain existing sheet and blank accounts; either purchase a

new CTL line for around $1 million, or if possible, upgrade the existing CTL.

Solution:

Coiltech

was commissioned to upgrade the existing CTL line to produce tight tolerance

sheets and blanks, increase productivity, and produce "solid block" finished

packages.

The

existing entry end equipment was saved, as was the leveler, shear, and

measuring table runout belt conveyor. The old hump table, positive stop, and

sheet stacker were discarded in favor of a new Precision Electronic Roll

Feed and a new Sheet Stacker and Weigh Station.

Development:

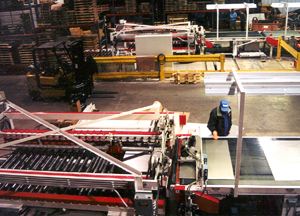

The new

equipment delivery schedule was established, and new CTL line engineering

drawings were prepared. About a week before the new equipment was due to

arrive, the old CTL line was de-commissioned to begin preparations for the

new line arrangement. The entry equipment through the leveler was left

untouched, remaining in existing locations, while the old hump table, shear,

measuring table, and stacker were removed. A shallow 20' long looping pit

was installed after the leveler, as was a new concrete footing for the old

shear. The new Servo Feed with the associated looping pit carryover tables

and loop quadrants was installed along with the old shear and measuring

table. Finally, the new Sheet Stacker with its elevating table and integral

scale was installed after the old measuring table was in place. The upgraded

CTL line was ready to run as a Precision Electronic Roll Feed Blanking Line.

Down time was about 2-1/2 weeks.

Results:

Precision Electronic Roll Feed

The

upgraded line was prepared to produce sheets and blanks to precision length

and diagonal tolerances, and was able to stack those sheets and blanks into

solid block packages. Productivity nearly doubled that of the old line

because; (1) the Servo Feed allows the leveler to run at a constant speed

rather than losing speed in its former slow down-positive stop cycle; (2)

new lengths are set-up by key pad operator input rather than trial and error

re-positioning a positive stop; (3) pack weights are recorded before removal

from the line, eliminating double handling; and (4) fresh pallets are power

injected into the stacker, minimizing time lost to unloading finished packs.

|

Automatic Sheet Stacker - Weigh Station

Allows Visual Sheet Inspection

Although the old measuring table belt conveyor

could have been eliminated from the new arrangement by installing the new

sheet stacker immediately behind the shear, the belt conveyor was

re-installed because it allowed each and every cut sheet to be visually

inspected for flatness and surface condition, and it allowed blanks to be

easily removed from the line for length and squareness verification without

interrupting production. Those operational benefits dictated the

re-installation of the runout belt conveyor.

Cost:

The cost to upgrade the existing CTL line to produce

close tolerance sheets and blanks was a small fraction of the cost of a new

CTL line. The increased productivity assured a quick return on the

investment, and the improved length and diagonal tolerances opened new

markets and assured the retention of existing accounts.

Conclusions:

Late 1960ís through early 1980ís hump table-positive stop

cut-to-length lines equipped with a corrective roller leveler are generally

well maintained and normally produce an acceptably flat sheet. But because

of the positive stop measuring system, they usually are deficient when it

comes to 21st century length and diagonal tolerance

demands and productivity. It is cost effective to upgrade those CTL lines by

replacing the hump table-positive stop measurement system with a

"state-of-the-art" electronic roll feed system. The new microprocessor based

motion control electronics are operator friendly, extremely reliable, and

incredibly accurate. As compared to "mechanical" type feed devices, the

electronic roll feed occupies much less space and offers quicker set-up

time, lower operating costs, significantly lower maintenance costs, and has

a significantly longer operational life expectancy.

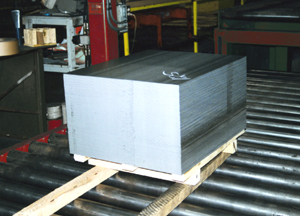

Solid Block Steel Packs |